Non-Woven Fabric The Characteristics Of The Fabric And Its Uses In Agriculture

Since the beginning of the petrochemical industries, non-woven fabrics were produced. Non-woven fabrics were initially used for their bulkiness and softness when used for packaging, covering, filling, and many other fields. Non-woven fabric has expanded their use to many different fields such as trade and civil engineering, agricultural and environmental engineering. Its presence can be seen everywhere, especially in its early applications in the field of agriculture. Non-woven fabrics can be described as materials that resemble fabric made of short and long fibers. They have been bonded with heat, chemical or mechanical treatments. The general rule is that woven textiles are stronger and last longer than non-woven materials. There are numerous uses for non-woven fabrics. Non-woven fabrics are more affordable than woven materials and the markets for them are expanding, developing maturing, and expanding. Follow this wholesale agriculture non woven fabric for recommendations.

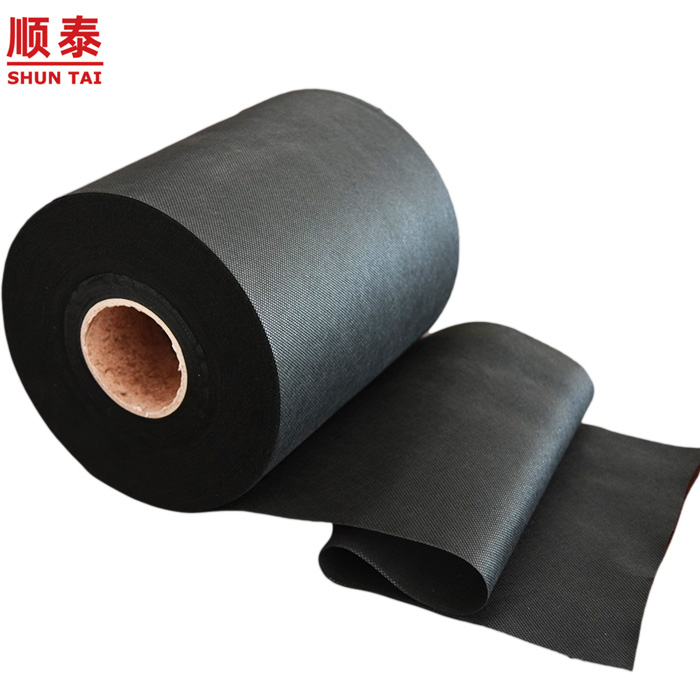

Non-Woven Industry Development. Nonwoven fabric is a product that emerged from the petrochemical and plastics industries after the introduction of film. It is lighter than plastic cloth and provides better airflow. It is commonly used in medical and sanitary products such as napkins for sanitary use as well as facial towels, filters and so on., and was later designed and used in engineering. Non-woven fabric can be utilized in the production of vegetable products to shield against the effects of cold. Non-woven fabrics are made differently from plastic films. But the fundamental components that are used in their production are almost identical. This includes polyvinyl chloride (PVC) (polyethylene), PE (polyethylene), EVA copolymer (Ethylene Vinyl Acetate), PVA/polyvinyl alcoholand many more. Through melting plastic and inflating the resultant thin film traditional plastic film can be produced. The film is continuous. It is able to stretch for a long time. The film has no pores. The film is inert and prevents any movement or exchange of molecules. With the development of the textile sector artificial chemical fibers fabricated of the mentioned ingredients became the new darlings of the business of textiles. Chemical fibers can still be used to make cloth by traditional weft and warp weaving. The non-woven fabric is created by interlocking fibers on the same plane, at different angles across all directions rather than using traditional warp and weft methods. When compared to traditional woven fabric the material has superior propertiesand its manufacturing process can go from raw materials to finished products in one step. It is less expensive than traditional weaving that involves weaving yarn into fibers and weaving. In recent times Non-woven fabrics have been frequently used in the garment sector. Recently, due to the advancement of material science as well as the advancement of production technologies non-woven materials have become more diverse and utilized in greater and greater quantities. The various materials and products made are present everywhere in our daily lives. The expansion of the use of non-woven textiles in agriculture is mostly due to their lightweight, simple production, low-cost as well as their diversity and variety of uses. Check out this non woven landscape fabric for more info.

Non-woven fabrics in the Agricultural Industry. Non-woven fabrics first appeared in Europe in 1978. They were utilized to keep carrots warm during early harvesting and prevent whiteflies and tomato leaf virus. In the United States non-woven fabrics are utilized for mulching cantaloupes, sweet peppers, tomatoes, root vegetables, carrots and radishes, cabbage lettuce, and many other vegetables. It is mostly employed for heat preservation, promoting early harvesting, and insect control. Non-woven fabrics are typically employed as covers for surfaces for grass-proof mats. A short fiber is utilized to create water-absorbing blankets that are applied to nursery beds, allowing the roots to completely absorb water. They can be used to produce turf, or as lawns for gardens. They are also used as planters for large woody plants, such as garden trees and fruit trees which help to control weeds and retain moisture. Non-woven fabrics, which aren't woven, are used in Taiwan to protect plants. Non-woven fabric is extensively used in greenhouses of large size for energy conservation and environmental control. Double-layered coverings and canopy curtains help reduce heat loss and radiation in the evening. TAVIK fabrics are high-density non-woven spunbonded TAVIK fabrics used in the early days of shading and protecting cauliflower bulbs. Its high shading capacity, low thermal conductivity and ease of recyclability led to it becoming a preferred choice for farmers. It was later used in the preservation of shade and preservation of leafy vegetables as well as the cultivation and protection of pineapples and fruit trees. The development of non-woven industries has been slow due to Taiwan's unique ecology and climate. The Taiwanese manufacturers of nonwoven fabrics are continuing to innovate nonwoven technologies. The primary focus of Taiwan nonwoven fabric production is on water absorption, air permeability, as well as water repellency. It has increased its research to improve its ability to preserve and store agricultural products and hopes that it can develop new applications. Check out this pp agricultural nonwoven fabric for more information.